RailCore® Labs

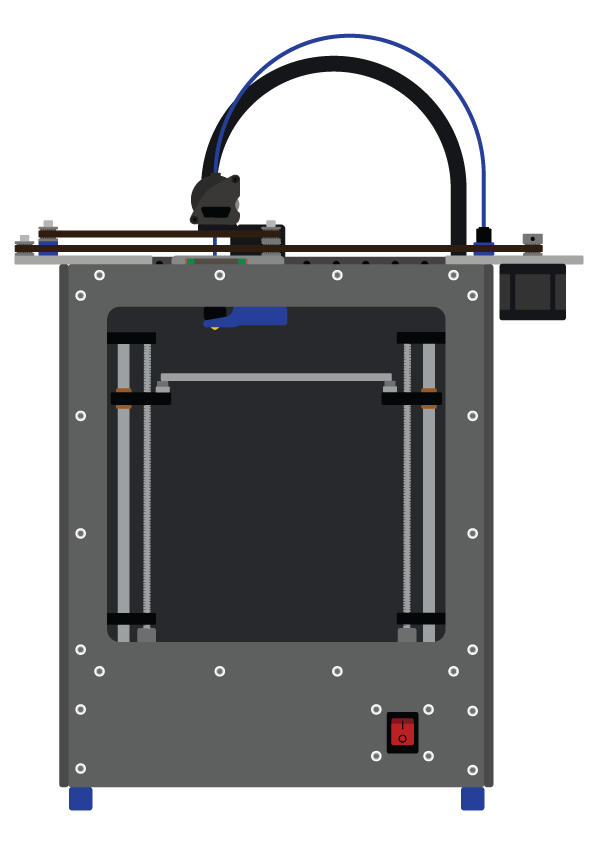

RailCore® is a family of Core-XY based Reprap 3D printers designed by J. Steve White, Tony Akens, and Ben Withem.

New Z alignment procedure for the Z extrusions.

Looking for some folks to help test this. If you have what appears to be Z banding, give it a shot. First, print this part (I recommend printing a few of them, it’s small).

To do this, you have to do the following steps (assuming a functional RailCore)

- Remove your bed

- Remove a leadscrew from the anti-backlash nut. Leave the bottom of the AB nut on. (unless you have the lower half of the nut on the bottom side of the yoke. if so, remove it)

- Remove your leadscrew coupler

- place the printed part over your stepper motor shaft. It will be a very tight fit, seat it fully.

- lower your yoke - ideally the hole for the leadscrew will fall nicely over the printed part. If so, you’re well aligned. Mine did not.

- loosen all 7 nuts on the top and bottom Z brackets.

- adjust until the yoke fits nicely over the alignment tool. BE CAREFUL YOUR CARRIAGE DOESN’T GO OFF THE END OF THE RAIL

- push the lower part of the Z extrusion firmly against the outside frame extrusion.

- tighten the lower Z bracket

- make sure the yoke still slides nicely on and off the alignment tool

- use a square, or 123 blocks to square the top of the Z extrusion to the frame.

- Tighten down the top bracket, making sure the Z extrusion is tight against the frame.

- Remove alignment tool

- reinstall coupler

- reinstall Leadscrew

This is pretty much the same process as before, but the alignment tool is a much more rigid attachment and alignment point and should give MUCH better alignment. It helped all of my leadscrews.

Another tip: test you can fit it on a spare stepper shaft BEFORE you pull your printer apart. Especially if you don’t have a second printer to print a new one.

It’s just a 5mm hole in one end of a 10.35mm diameter cylinder, 25mm long.