RailCore® Labs

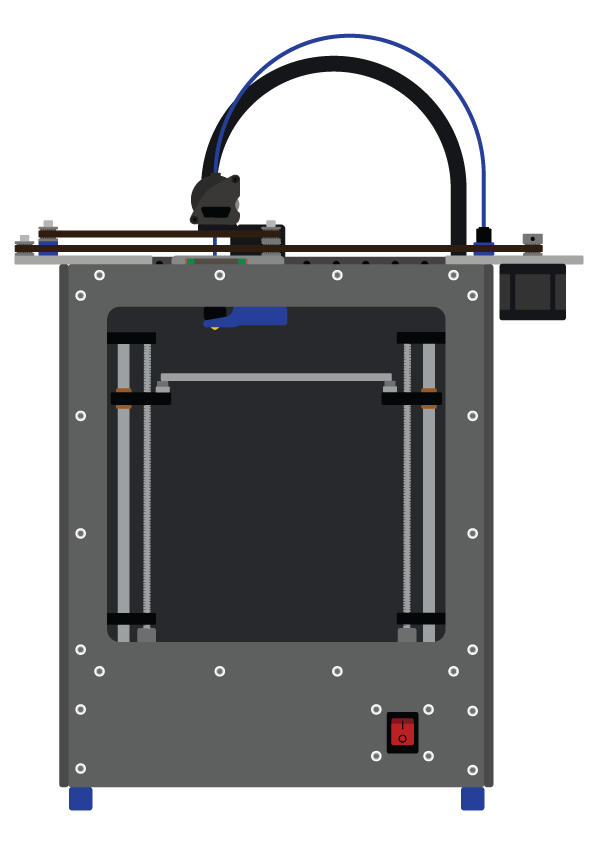

RailCore® is a family of Core-XY based Reprap 3D printers designed by J. Steve White, Tony Akens, and Ben Withem.

5m of belt is enough to do both belts on either printer. The 300ZL is roughly 2.2m of belt per side.

NOTE: when planning to change from printed to aluminium idler and motor mounts add several cm extra length to your belts as the aluminium idler mounts will move the idlers further outside than the printed idler mounts.

To assist with belt tensioning measure belt frequency using a tool such as:-

- a guitar tuner

- a guitar tuner app on your mobile

- “Gates Bicycle Belt Tension Meter” app

- Gates Carbon Drive app

The belt returns on the left, between the two idlers where the belts crossover, should be around 41Hz (40-45Hz should be fine) on the 300ZL series and 50Hz on the 250ZL series, according to Gates’s DesignIQ software.

Caveat: The Gates software almost certainly optimizes for belt life and power transmission. It’s entirely possible that a higher tension might shorten the life of the belts but result in better prints in some fashion, so YMMV. These numbers are just what Gates DesignIQ says, and a place to start.